Publication Link | Download PDF | Cite This

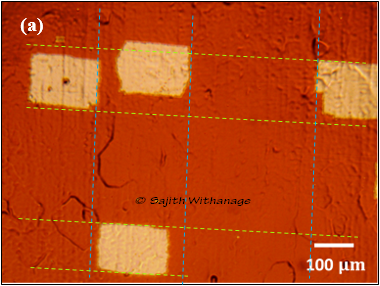

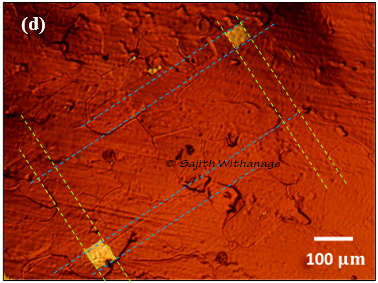

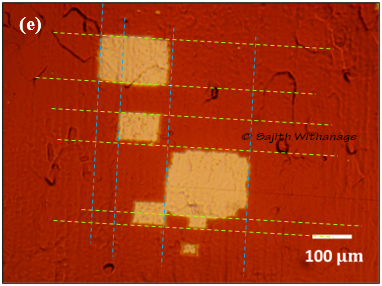

Abstract: Graphene has attracted enormous attention due to its unique characteristics. However, the LPCVD graphene grown on copper turns out to be polycrystalline because of the high nucleation density (ND) on the copper foil surface. In order to realize better quality LPCVD graphene, this ND needs to be significantly reduced. Based on the observations from our initial graphene growths on as-received copper, we figured that the uneven Cu surfaces with defects produce large NDs. At a large ND, the graphene flakes nucleated at different sites coalesced to produce polycrystalline graphene. Due to such issues, we have implemented an electropolishing technique to smoothen the native surface of the copper foil. We will discuss the successful implementation of the surface smoothening process to reduce nucleation site formation while limiting the surface defects (which leads to wrinkle formation). The annealing process was also helpful to flatten the surface during the growth process further. We have also observed that graphene grows across Cu grain boundaries and, in the process, produces an additional surface area for graphene growth. That later causes to form wrinkles, which affect graphene properties negatively.

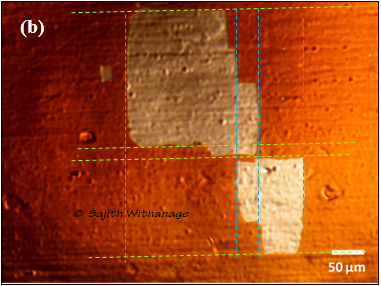

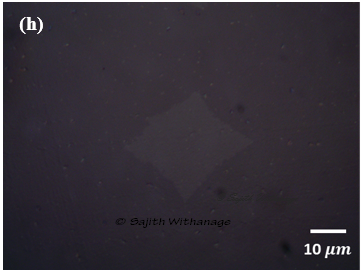

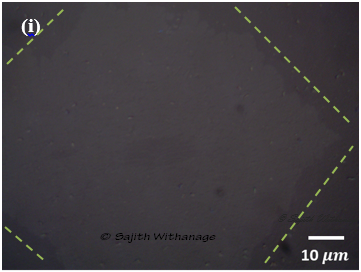

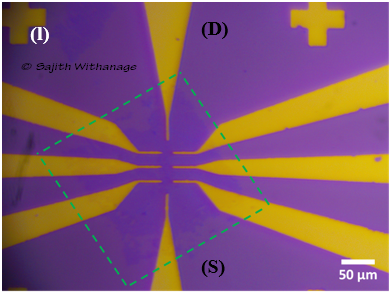

In the next project, the effect of multi-step copper surface oxidization, base pressure vacuum in the middle of the process, and integration of Cu enclosures on suppressing the ND will be discussed. The technique is based on the self-cleaning characteristics of copper oxides and the metal evaporation in a high vacuum at high temperatures. The ND has reduced to ~5 nucleation per square centimeter on average (an improvement compared to the previously reported minimum value, ten per square centimeter which was obtained using copper enclosures), and the graphene/copper surface has become smoother. The self-aligned graphene island geometry and shape of the flakes have reflected the symmetry and the single crystallinity of graphene.

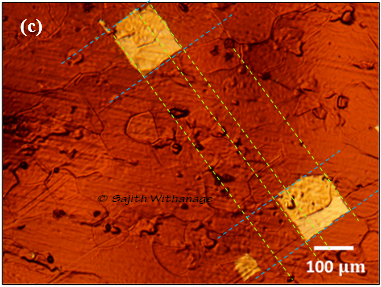

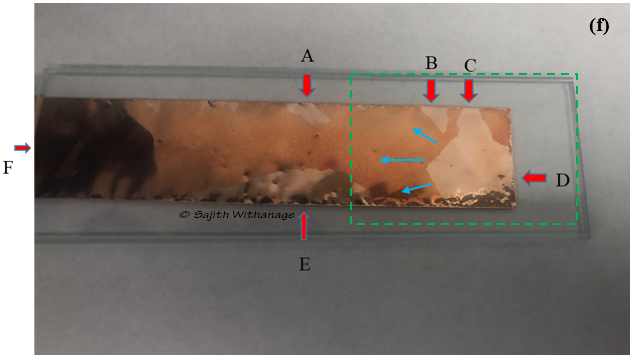

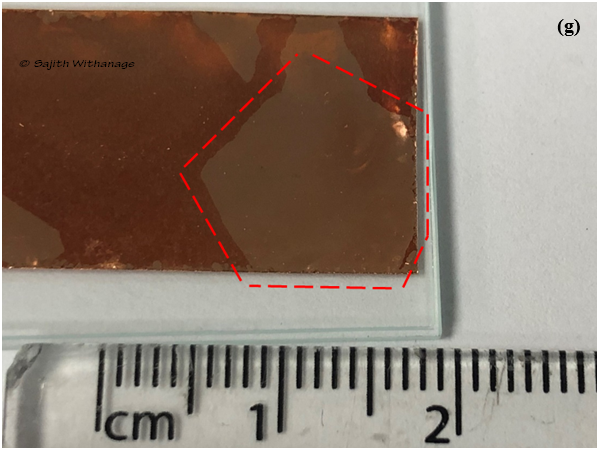

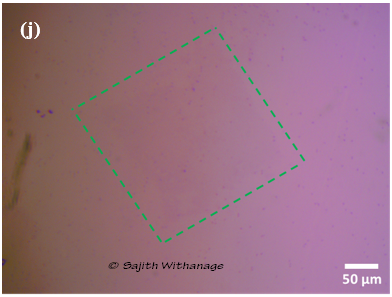

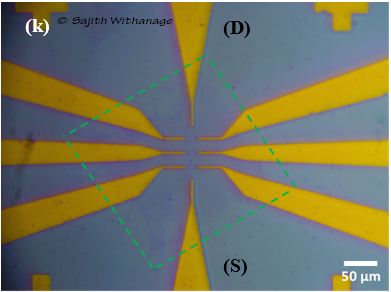

The final project will discuss the growth of cm-scale graphene flakes on Cu and 3D-multilayered graphene on 3D-Ni foams and used Ni’s gettering carbon diffusion effect to make the Cu foil carbon-free. The Ni-foam/Cu enclosure was oxidized in situ to assist with the self-cleaning process of metal oxides. The ND has been reduced to ~0.57 per square centimeter and obtained cm-scale graphene flakes.